Reusing and recycling decommissioned materials: Is the glass half full or half empty?

A collaborative project between J+S Subsea Ltd and Heriot-Watt University, funded by the Scottish Institute for Remanufacturing

Decommissioning as a societal issue

The North Sea (in specific the UK Continental Shelf) is one of the first regions globally to undergo mass decommissioning. The need to remove man-made infrastructure from oceans was established by the Ospar Decision 98/3 (1998); however, removing the 4.5 million tonnes of infrastructure at sea is proving to be a challenging and costly undertaken. It is also an activity of public interest for two reasons. Firstly, the taxpayer will be affected due to tax reliefs (which will likely vary from £17 to £58 billion over the next few decades). Secondly, decommissioning involves a high environmental impact and presents a perfect opportunity for Scotland to truly establish themselves as a leader in the circular economy.

The current system: half-empty glass

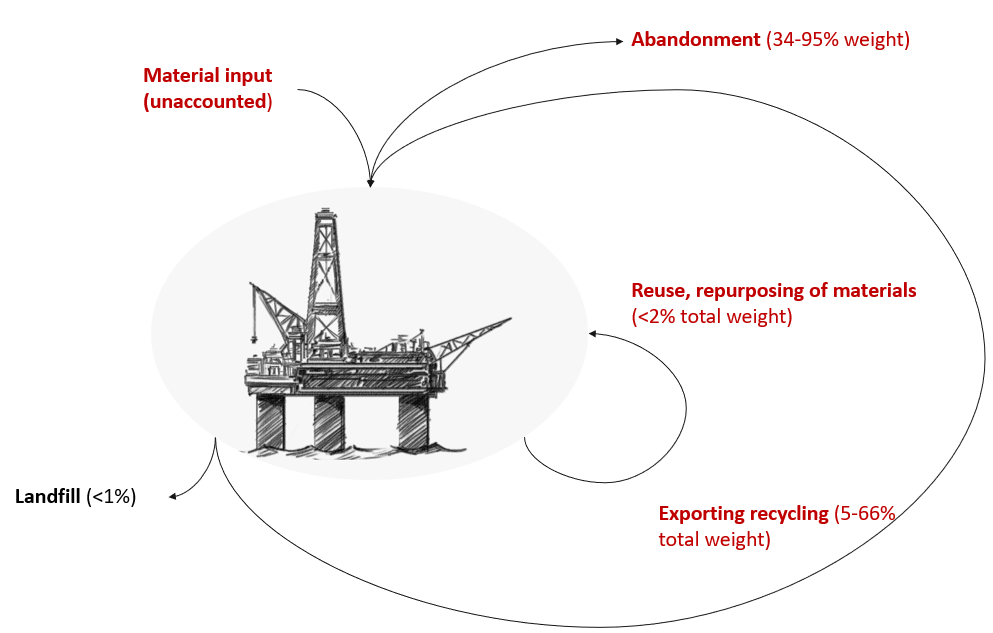

Aiming to understand the drivers and barriers related to reusing decommissioned materials from a systems perspective, we collected evidence from several decommissioning plans and close out reports and through 15 in-depth interviews. As a result, we created a picture of the current circularity of the decommissioning system. At present, much of the topsides and structural of platforms are being left at sea and most materials recovered go to recycling.

Although operators and regulatory bodies might view recycling as a good solution, most steel is being sent to countries with a more polluting energy grid than the UK. Thus, the recycling of steel emits only 30% less CO2 compared to the manufacturing of virgin steel and there are limitations in terms of the purity and quality of the final product (Allwood et al., 2019). Although reusing materials from the North Sea could ultimately save over 4 million tonnes of CO2, the reuse or remanufacturing of parts and equipment is currently negligible.

Drivers of reuse in Oil and Gas

The oil and gas industry, particularly in Scotland, is no strange to reuse and remanufacturing. During the platform operating stage, businesses built upon such circular principles thrive. Operators are driven to repair, reuse and remanufacture their equipment to obtain a cost reduction compared to a new product. However, more than cheaper costs, operators are interested in the reduction in turnaround times and in the specialised knowledge and services that local companies in the Northeast of Scotland are capable of offering. Other less specialised companies also created a niche business for themselves, selling particularly surplus or barely used standardised equipment such as turbines, engines and pumps.

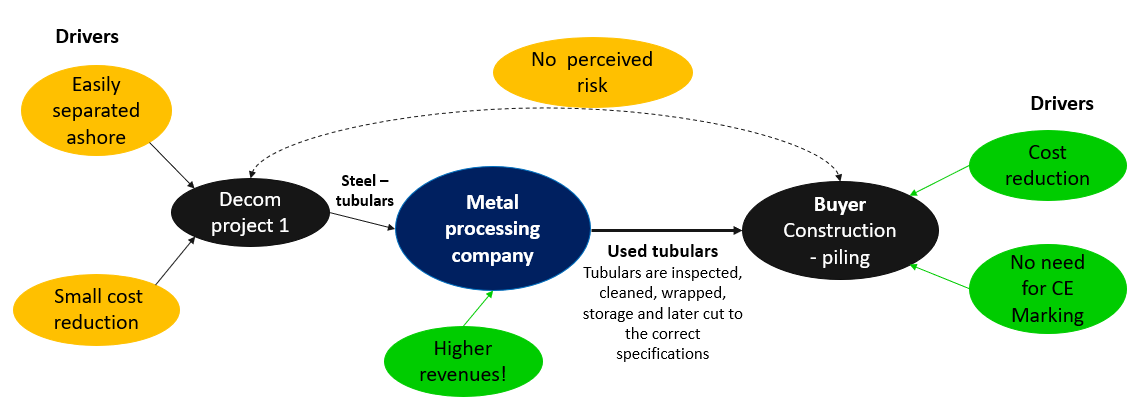

However, when it comes to the decommissioning activity, the scenario changes. Contrary to the operating stage of platforms, examples of reuse of decommissioned materials are scarce. Ad hoc examples are cited – a few pumps or turbines which were recovered, food and gym equipment which were donated, one accommodation block that was purchased and refurbished by the contractor, or a few lifeboats that were sold. Notwithstanding, these examples are not consolidated and published in the public domain. Perhaps the most known case of reuse of decommissioned materials refer to ‘tubulars’ which have an established route from metal yards to the construction industry. By reusing ‘tubulars’, the supply chain is able to create higher revenues.

Barriers to reuse in decommissioning

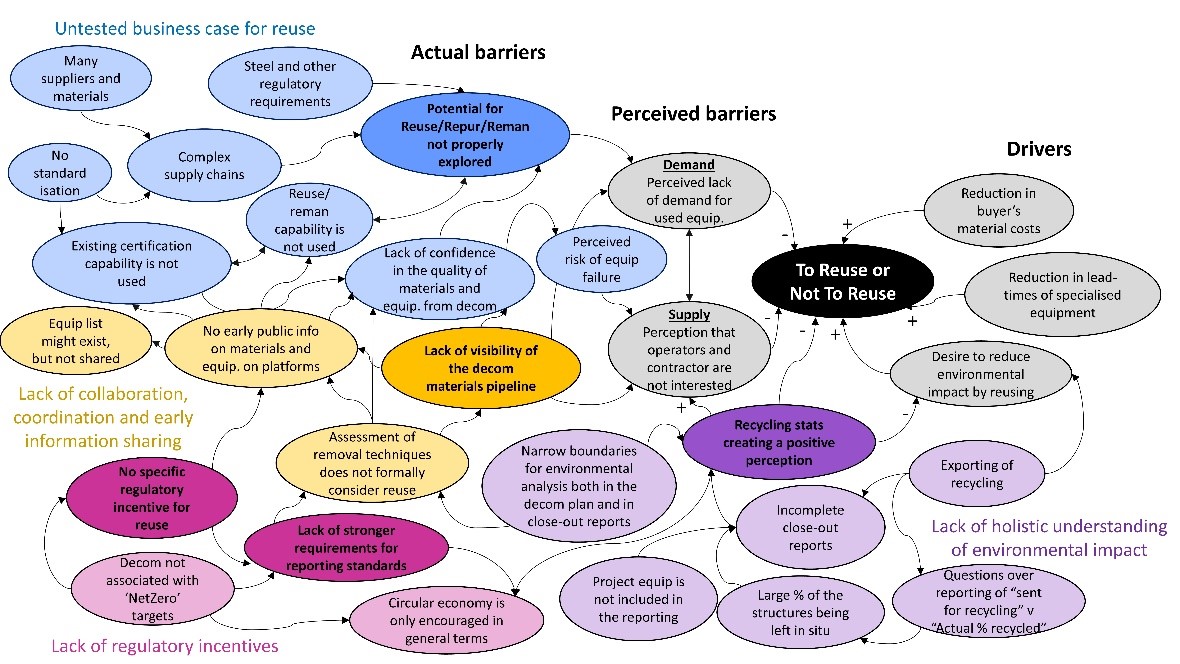

This project analysed the barriers to reusing materials decommissioned from offshore platforms in the North Sea. With the data collected from in-depth interviews, the ‘perceived’ barriers were coded. Subsequently, by taking a system approach, the analysis focussed on underlying barriers. For instance, although ‘bespoke equipment’ and ‘lack of demand’ are perceived to be barriers, the supply chain has the skills and know-how to overcome such issues if more information regarding the offshore equipment was shared in a timely manner. The ‘actual’ barriers identified were: the untested business case for reuse; the lack of collaboration and early information sharing; underpinned by a lack of regulation; and, ultimately, a lack of understanding of the true environmental impact associated with decommissioning. In addition to previous recommendations in the literature, we proposed simple interventions that would contribute to information sharing and enhanced collaboration across the supply chain:

- Publishing inventory lists with details of the materials and equipment on the platform in the public domain early, ideally as a requirement within the decommissioning plan by OPRED.

- Maintenance of an online repository of all successful reuse case to help benchmark.

- Requiring more details regarding the materials reused within the close-out reports, including the materials used during the project.

The future system: filling the glass

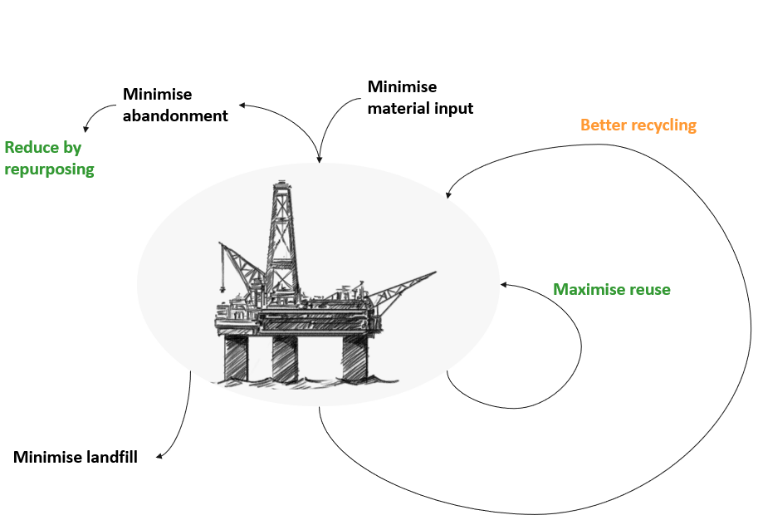

A circular economy involves reducing the material input to the system. We highlighted that there are ongoing debates surrounding the premise of a need to decommission. Instead, repurposing platforms to varied types of energy production or as artificial reefs could be more environmentally friendly (Fortune and Paterson, 2020).

Assuming that decommissioning (at least of topsides) must take place, recycling in countries with a cleaner energy grid such as the UK would have a positive impact. However, reusing equipment would be a much better solution and our recommendations contribute to that. The economic and environmental impact of reuse is a topic for future research. Nevertheless, it is expected that reuse would save carbon emissions, create jobs and place Scotland in an advantageous position to export the skills created to other regions in the future.