How effective is a Circular Economy business model?

A collaborative project between Clyde Blowers Capital Ltd and Heriot-Watt University, funded by SIR

A growing global sector

Growth in the circular economy is increasing year on year as awareness and opportunities increase. The remanufacturing sector was valued as USD 43 billion in the US, GBP 6.9 billion in the UK, and GBP 1.1 billion in Scotland, yet understanding of business models for the circular economy is limited.

The focus of Clyde Blowers Capital is to invest in mid-sized engineering companies and to work closely with them to turn them into global market leaders in their fields. Clyde Blowers is engaged with companies from sectors such as oil & gas, renewables, power, water, mining & minerals and general industry.

Over the last few years, researchers from Heriot-Watt University and Clyde Blowers have been independently involved in numerous circular economy projects in Scotland and beyond. A wide range of methodologies have been applied to create Circular Economy Business Models (CEBMs), but the aggregate lessons and knowledge had not been formally captured. The Scottish Re-use and Remanufacturing sector is aware of the need to understand what drives value creation to support the transition to a circular economy.

Thus, this collaborative project aimed to;

- develop a set of generic CE business models;

- develop a business modelling framework from a CE perspective.

Understanding value in the circular economy

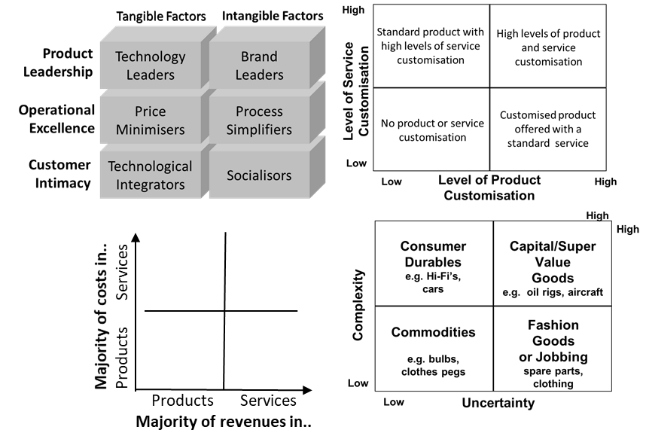

The research team analysed 16 manufacturing organisations engaged in remanufacturing or repair activities, 8 classified as OEM (original equipment manufacturers) and 8 classified as non-OEMs. The team began by analysing existing circular business models by using tools such as the Business Model Canvas (Osterwalder and Pigneur, 2010) and others as shown in the figure below.

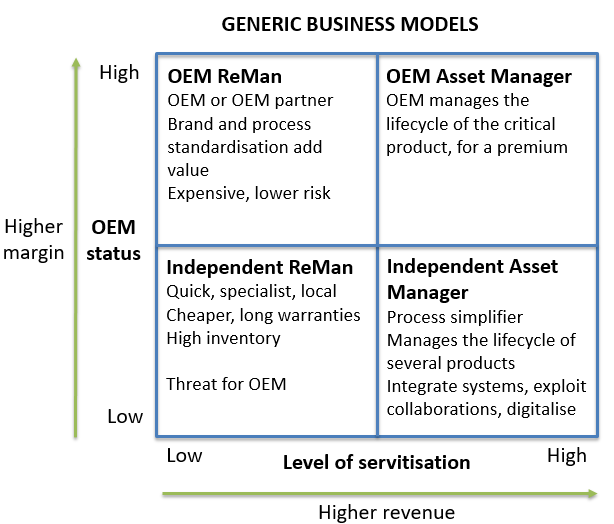

The most important variables of value creation in the 16 companies analysed were ‘OEM status’, which contributed to higher margins in the cases studied, and ‘level of servitisation’, which influenced the size of the business.

Some OEM-associated firms in the analysed cases were able to exploit the brand and reputation and enjoyed higher margins. However, for the majority of companies value creation in the remanufacturing/ repair side of the business was related to operational excellence, i.e. being better value and faster than any competitor. Additionally, some independent remanufacturers and OEM firms increased the services they offered in order to grow, sometimes providing remanufacturing or repair services to several brands other than their own to give convenience and simplification to the client. As a result, these companies observed a transformation in their business model over time from manufacturers to independent service providers. With regards to costs, although it is commonly suggested that remanufacturing reduces material costs, it was observed that a few firms had to cope with uncertainties related to demand and supply. As a result, a large inventory of remanufactured products was maintained, which assisted them dealing with uncertainties and deliver fast turnaround, albeit at the cost of trapped capital.

Towards a circular economy business model

Analysis of business model literature and the operations of the 16 remanufacturing organisations has led to the team proposing four types of generic business models. Current literature identifies a reduction in material costs as the main driver of value creation. This is quite an unrealistic view as the reduction in material costs often do not compensate for the extra costs inherent to remanufacturing. In contrast, these findings reveal that the level of servitisation and the degree of OEM-association were the main enablers of value creation in remanufacturing companies.

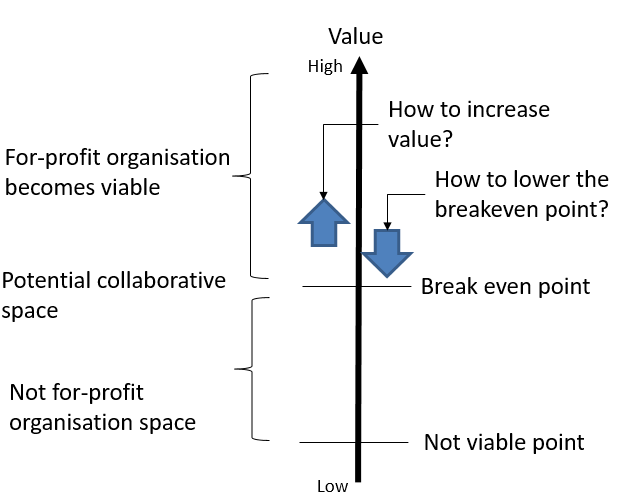

Furthermore, due to the challenges related to value creation in remanufacturing, the team identified the potential for collaboration between for-profit and not-for-profit organisations, as not-for-profit companies could help lowering the break-even point thus making circular businesses viable.

In relation to the second objective, the analysis suggests that the business model canvas is a useful but insufficient framework primarily due to its inability to capture all relevant information and portrait the dynamics of the product and the business over time. Therefore, when using the tool in the repair and remanufacturing context, the organisation should keep in mind the following points:

- Is competitiveness in the business dependent on the OEM status?

- What is the level of servitisation in the business? How is it affecting revenues and profit margins over time?

- Can we further explore collaborations with other businesses and not-for-profit organisations?

- Is there a possibility of innovating, or customising the product or service offer?

This project has highlighted that there is a range of value creation patterns across remanufacturing and repair businesses, from exploring the full benefits of a leading OEM brand to a more servitised offer that simplifies customer processes. Nevertheless, most firms compete through operational excellence, for instance trying to minimise price, and thus there are blue ocean opportunities related to creating a customised product offer or achieving customer intimacy.

Moreover, repair and remanufacturing firms have to manage additional challenges such as uncertainties and the difficulty of maintaining a focused and profitable business as the technology ages and the service unit of the firm grows. Businesses therefore need to keep asking themselves fundamental questions about their core capabilities and focus constantly. The project findings can be utilised by remanufacturing and repair companies to reflect upon value creation, the dynamics of the firm over time and the potential for making circular businesses viable through the collaboration with not-for-profit organisations. This research therefore contributes to advancing circular models within Scotland, ultimately making firms more profitable whilst reducing waste to landfill in the long term.